Heat is the major limiter of electronic components and systems. It

frustrates engineers trying to squeeze extra watts or even milliwatts

of functionality into a design--functionality that can mean the

difference between leapfrogging competition and lagging behind.

In order to optimize a thermal design, engineers typically set up

and solve multiple cases and then compare the results to find the best

performing configuration. This process can be incredibly

time-consuming. A designer can spend 40 hours or more setting up test

cases and analyzing results, with no assurance that he has picked the

correct values to test. This "Value-picking" strategy is often

hit-or-miss because design sensitivities are not always intuitive.

To eliminate the guess-work and simultaneously shrink the design

cycle, engineers need to automate thermal optimization. Automation

transforms thermal analysis into a faster, more effective, more

efficient process, and guarantees that engineers will examine all

possibilities. With automation, all heat sink dimensions, vent and fan

locations, properties, etc. are investigated. If there is a

combination of parameters that can make the design goal possible,

automated optimization will find it.

OptimizeIt, a module integrated with Coolit CFD thermal and flow

analysis software, delivers this automation. Users merely define what

design parameters can be varied, their ranges, and the objective of the

design optimization. They then click "Start", and walk away;

OptimizeIt takes care of the rest. Using a sophisticated optimization

algorithm, it sets up and runs multiple Coolit cases and identifies the

best design.

Telecom Challenge

While any industry can benefit from thermal optimization,

telecommunications, with its NEBS requirements, can profit more than

most. NEBS, or Network Equipment Building System, is the universally

recognized standard for telecom equipment. It requires equipment to

operate in a 55 deg. C ambient while maintaining electronic component

case temperatures below the manufacturer-defined maximums, typically 80

- 95 deg. C.

At CAS Ltd, we recently designed a telecom chassis for telecom

manufacturer, Actelis Networks. Actelis supplies high-quality,

high-bandwidth broadband services over existing copper pairs for a wide

range of businesses, utilities, military installations and government

agencies.

The chassis was a 1U configuration (1.75 inches high) and 9.5 inches

wide, dissipating approximately 35 W. The design goals were to ensure

that several temperature sensitive components were within their

manufacturer's limits, while at the same time optimizing fan type and

location, and the number, sizes, and locations of vents. Standard,

commercially available, pin fin heat sinks were chosen. If optimizing

the above parameters was insufficient to maintain the required

component temperatures, we could have added heat sinks to the

optimization process. However, that would have required custom and,

hence, more expensive heat sinks, which was undesirable.

To optimize the design we used Coolit's OptimizeIt module. The

initial design had one fan and 4 vents. It had several key electronic

components on both sides of the PCB whose temperatures were at, or

exceeding their manufacturers' limits. The hottest device, a BGA on

the component side of the board, was 5 deg. C over its 91 deg. C limit.

In OptimizeIt, we specified the maximum allowed component

temperatures as the design constraints and objective functions. We set

the number, size, and position of the vents and fans as variable

parameters.

OptimizeIt automatically set up and ran 73 cases and reported that

the design goals could be accomplished with a single Delta 40mm exhaust

fan positioned roughly in the middle of the back wall. It also resized

and repositioned the existing vents, and added an additional vent to

the front panel. In the optimum design, the BGA temperature dropped

from 96 deg. C to 88 deg. C, while the case temperatures of the circuit

side components fell from 95 deg. C to 89 deg C.

If we had to perform the optimization manually and solved the same

number of cases as OptimizeIt, we would have spent an average of 30

minutes per case setting up and comparing results. In total, it would

have added almost a week to our project, and resulted in a

correspondingly higher price to the client.

Optimizing At Any Level

OptimizeIt is an effective tool for pinpointing the optimum thermal

configuration at any level, from individual heat sinks to complete

systems. It frees engineers from the iterative, and potentially

tedious process of setting up numerous cases and comparing the results.

The iterations still occur, but problem-setup occurs automatically with

the results ranked in order of thermal performance. The time savings

are huge, amounting to man-weeks of manual inputting and analysis that

are off-loaded to a computer, leaving engineers to focus on tasks only

they can handle. On top of that, engineers no longer have to worry

that they might miss the best configuration. OptimizeIt will always

find it.

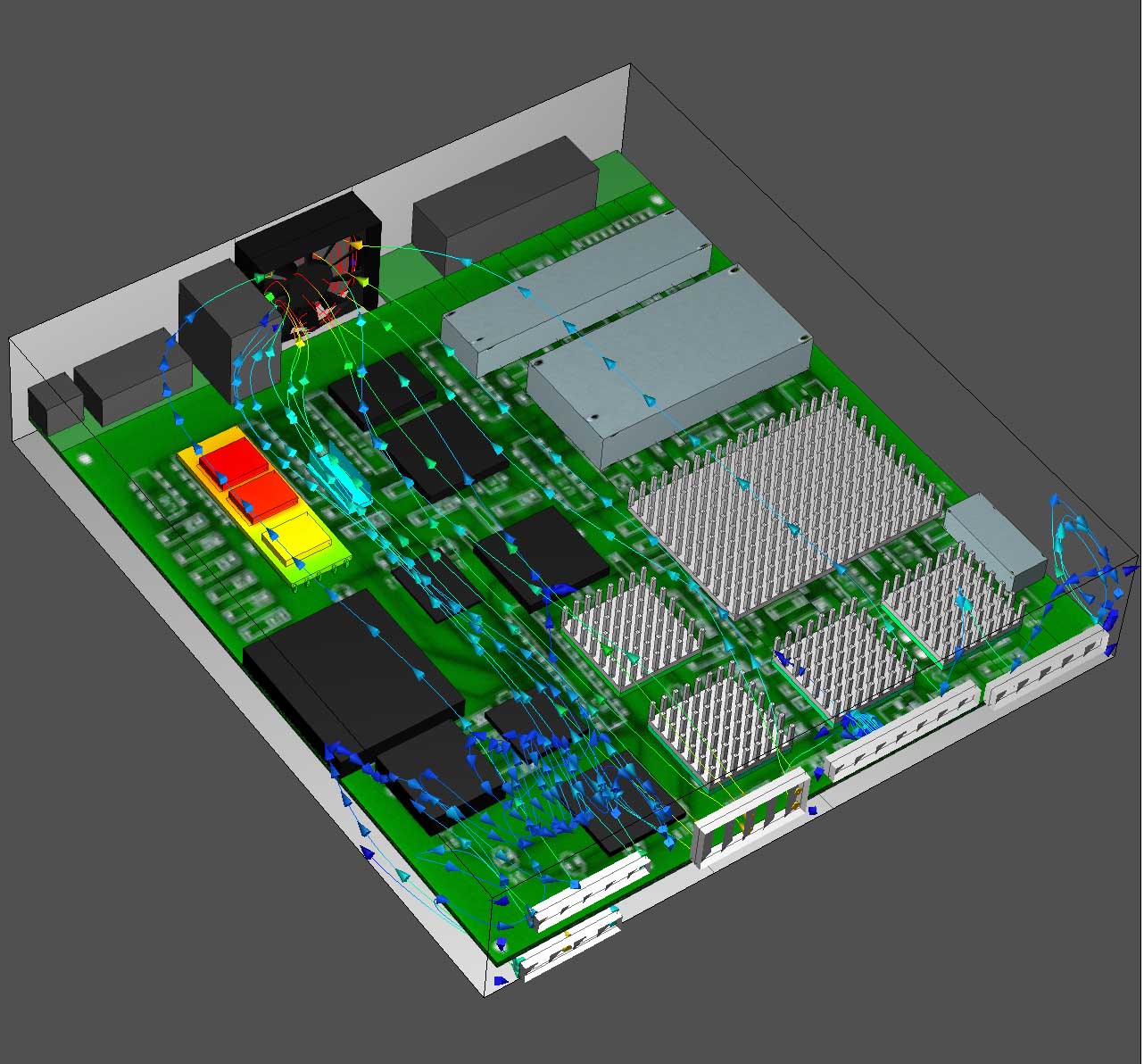

This view inside the telecom chassis identifies two hot components

that were insufficiently cooled in the original design. OptimizeIt

repositioned the existing vents, and added an additional vent to bring

temperatures within spec.

Thermal optimization ensured that this telecom chassis from

Actelis meets NEBS requirements for operating in a 55 deg C

ambient.