|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

v.21 release of Coolit permits the Enclosure heat transfer coefficients to be time or temperature dependent, adds the option of importing/exporting components' information to spreadsheets, allows radiation to ambient envrionment, improves the display of the temperature fields and fixes bugs. These are just a sample of advances implemented in the new version.

v.20 release of Coolit speeds up the solver initialization time drastically reducing the start/restart times, adds Gerber format for importing PCB traces, improves the grid generation algorithm and adds new reporting tools to CoolPlot. These are just a sample of advances implemented in the new version.

The latest v19 line of Coolit products for thermal management of electronics delivers major improvements in usability and functionality. The expanded functionality of the Objects Manager, automated import of CAD into Coolit objects, improved solver restarts are just a few of the new features and improvements implemented in this release.

Plate fin heat sinks cooling encapsulated power transistors is one of the most common configurations used for thermal management of electronics. One of the difficulties associated with modeling such configurations is flow regime. In this study we used Coolit with its specially tuned turbulence models to predict flow in a wind tunnel with a flush-mounted heat sink on top of an encapsulated power transistor. The computed results were compared to experiment by Ventola et al (2016).

For this paper the flow around a single wall-mounted obstacle was selected. Both the problem geometry, resembling a building block in electronics and low Reynolds number flow are characteristic of electronics cooling applications. Due to its “classic” configuration, the problem has attracted attention of experimentalists and reliable data are available to benchmark CFD against.

With release of the v.18 line of Coolit products, Daat Research delivers numerous improvements in product usability and functionality. The release expands functionality of existing components, adds new components, and new functionality. An optional IC package import function has been included.

Encapsulated phase change materials (PCM) are finding an ever wider application in thermal management of electronics and data centers. PCMs have high fusion capacity and can absorb large amounts of heat when melting and release heat when solidifying. PCM component has been implemented in Coolit and in this white paper we will use it to assess the accuracy of the implemented model against both analytical and experimental results.

The new release of Coolit® and CoolitPCB® v.17, the first 64-bit only release, makes significant strides in boosting CFD user productivity. The release expands functionality of existing components, adds new components, and new functionality. An optional data center modeling module has been included.

Daat Research Corp is celebrating 25 years since its founding in 1992.

The new release of Coolit and CoolitPCB v.16 is Windows 10 compatible and provides impressive new functionalities further enhancing the ease of use, improving workflow, and increasing the user satisfaction and productivity.

At one giant EU pharmaceutical company, AMS engineers were enlisted to create an incubator environment that would ensure a uniform temperature distribution around all reagents of +/- 0.1 oC. The incubator was the size of a home refrigerator and sat in an ambient that could vary as much as 15 oC. While the incubator was cooled by a thermoelectric air conditioner, the electronic controls and motors for reagents-handling added a heat load that raised the temperature.

At Textron's AAI Division in Hunt Valley, MD, unmanned boats for military and commercial applications are a specialty. Recently its electronics designers developed a common marine power panel for installation in a boat engine room. The six-sided panel could house any of several circuit configurations, some of which produced high heat loads. When the configurations were submitted for thermal analysis, the electronics group dictated that the circuits were fixed, and nothing, not even the thermal pads could be changed. Using CFD modeling, Textron thermal engineers delivered a design which met all the constraints.

The new release of Coolit and CoolitPCB v.15 is an order of magnitude faster when working with complex CAD-imported objects, provides up to 40% solution time cut for most problems and an additional up to 50% boost for forced convection flows with difficult (multivalued) fan curves.

Many fan curves are multivalued, so that a single value of the pressure drop corresponds to more than one flow rate. Such behavior presents often an insurmountable problem to CFD codes resulting in divergence or slow convergence or convergence to a wrong solution. In this white paper, the physics of the problem is discussed and benefits of a recently discovered solution are noted.

Accurate thermal predictions are critical during new product development because they impact product design, schedule, and cost. During an Intel benchmark of two top CFD codes, Coolit consistently delivered superior accuracy with predictions to within 5% of experiment.

In the latest release of its award winning Coolit and CoolitPCB CFD software, Daat Research has significantly shortened the calculation time for complex transient problems. Version 14 incorporates a new algorithm that often delivers results over 10 times faster than before.

A key goal in designing Smith Optics' new Overtake cycling racing helmet was minimum wind drag. Normally Coolit is thought of as electronics cooling software, but it is a great choice for purely aerodynamic problems as well. It readily imported the extremely complex helmet geometry and did the required aerodynamics simulations. Full Navier-Stokes equations were solved to account for subsonic fluid flow. Powerful turbulence models to deal with complex aerodynamics at high Reynolds numbers were utilized in this simulation.

Cost-effective thermal design demands the right tool. For electronics, that tool is CFD which optimizes thermal designs, improves product reliability, shortens development cycles and cuts costs. The case histories in this white paper demonstrate how various industries have benefited from CFD thermal analysis.

One of important Intel product lines for the electronics industry and consumers are RAID controllers used for the purpose of data redundancy and performance improvement. Intel RAID modules incorporate RAID-on-Chip (ROC), DDR3, heat sinks etc. from a major manufacturer. These components and assemblies often come with Coolit models providing predictions of their performance and verified with experiment.

Before releasing a new solid state drive (SSD) to production, SanDisk uses CFD to verify that its design will meet the thermal requirements. To perform the analysis, SanDisk relied on Coolit, CFD software designed for electronics cooling application. In this project, Sandisk was assisted by CAS Ltd - a leading thermal design consultancy. The design had to be tested at high altitude conditions with an ambient temperature of up to 70C.

In the latest release of its award winning Coolit CFD thermal software for electronics, Daat Research has dramatically shortened the calculation time. Coolit v.13 incorporates a new solver that delivers results up to 20 times faster than before.

The Kinect system inside Microsoft's Xbox contains motion sensing technology that allows allowing Xbox players to use their bodies to control the movement of their on-screen characters. The system's design, contains powerful electronics in a compact box. With the aid of Coolit, multiple configurations were analyzed and a layout was developed that met both the power and size constraints. The successful technology is now found in millions of homes.

Daat Research announces a break-through in Coolit design that increases solution speeds up to 20x of previous versions.

The new Abbott Labs server developed for its specialized needs, consisted of a multi-chambered system with processor, function boards, power supply and fans and a spiral heat sink mounted on the processor board. Thermal modeling by consultants confirmed the Abbott's fears that the server had inadequate cooling. Using Coolit CFD software, thermal consultants from Byrd Technology Group, delivered in record time a thermal design that met all of Abbott's requirements.

Owners of Audi automobiles can keep their beverages hot or cold thanks to a thermoelectric cup holder mounted in the console. The heating/cooling system faced multiple design constraints. Its thermoelectric modules and associated fan had to squeeze into limited space, consume minimum power, and the fan noise had to be kept to a minimum. Using Coolit, thermal consulting firm, AMS Technologies, Martinsried, Germany, produced the design which could cool the beverage to 2 deg. C with overall power consumption of only 36 W. The design achieved the best performance among several competing automotive suppliers and was selected for production. Since start of production, many tens of thousands of the thermoelectric cup holders have been installed.

Daat Research Corp. announces a release of new Coolit v. 12 CFD software for thermal design of electronics. The new release introduces a wealth of new enhancements for its award winning Coolit CFD thermal software for electronics. The new features boost accuracy and further enrich the software's intuitive interface.

VT Miltope's Mass Memory Server 2 (MMS-2), which resides in the aircraft's hot, cramped avionics bay, is a lightweight, networked, solid-state storage platform that is part of the helicopter's Avionics Management System. It serves as a digital map server and collects aircraft data including usage, maintenance, vibration monitoring, and engine, rotor, and balance information in order to monitor aircraft health. Harsh environment placed very tight limits on modeling accuracy to ensure a reliable cooling system design across an operating temperature range of -40C to +71C. Coolit predicted that all major components would remain within their manufacturer's specifications with a healthy thermal margin. This modeling outcome later was verified by thermocouple measurements on pre-production hardware.

When excessive heat threatens your data center, you can throw CRACs at the problem if you don't mind soaring power bills and equipment costs. A more efficient way involves CFD analysis, a simulation technique used by electronics manufacturers to optimize thermal designs. Using CoolitDC CFD software can pinpoint the optimal thermal solution and pay for itself through lower costs, greater energy efficiency and improved reliability.

Daat Research Corp is celebrating 20 years since its founding in 1992.

Optimizing data center design is a challenging task, frequently requiring dozens of models to zero in on an optimum solution. A fast, highly accurate CFD tool is a must. Israeli consulting and thermal modeling firm, CAS Ltd used CoolitDC to boost performance, efficiency and reliability of data centers at France Telecom and at Israel Defense Force Data Centers.

At a new IBM location, the company's data center takes up the entire middle floor of an office tower, so there is insufficient height for both a raised floor and a suspended ceiling. This structure necessitates a design where the CRACs, instead of pumping cold air down under the floor, pumped the cold air up above the ceiling. Such designs are often problematic, since the cold air could be readily "shorted" from the racks and instead go back into the hot portion of the room and to the CRACs. Using CoolitDC, the company analyzed various data center configurations and within a few days pinpointed optimal design requiring minimum construction and maintenance costs as well as delivering excellent energy efficiency.

At the Israel Defense Forces data centers, reliability is an absolute must. The critical and often mobile nature of the applications demand that the data centers run cool even under harsh conditions, and often it impossible to incorporate spare capacity for backup. To boost reliability, as well as efficiency and capability, Israeli consulting and thermal simulation firm, CAS relies on CoolitDC.

Daat Research Corp. announces a release of new CoolitDC v.5 CFD software for thermal design of data centers. The new release includes numerous enhancements that add functionality, increase modeling speed, and further improve ease-of-use, the trademark of Coolit software since 1996.

In a head-to-head comparison CoolitDC, the CFD software from Daat Research Corp., has trumped major competitors in the data center arena. An analysis performed by Degree Controls Inc., Milford, NH, on two data center applications with different thermal challenges, revealed that CoolitDC offers distinct advantages in handling complex problems accurately and with a minimum of computing resources.

Daat Research Corp. announces a release of new Coolit v. 11 and CoolitPCB v. 7 CFD software for thermal design of electronics. The new release includes numerous enhancements that add functionality and increase ease-of-use, the trademark of Coolit software since 1996.

Daat Research Corp., developer of the Coolit family CFD thermal and flow analysis software, announces a partnership with Shanghai-based BPSolution Co. Ltd. to deliver innovative CFD software and solutions to the Chinese market.

Daat Research Corp., developer of the Coolit® family of CFD thermal and flow analysis software, announces a release of a new member of the Coolit family: CoolitDC - CFD software specifically designed for thermal management of data centers.

When one of the largest telecommunications companies in the world, France Telecom (Orange), wanted to boost performance in two data centers, the company enlisted the help of thermal design experts, CAS, Ltd to perform a CFD analysis and make recommendations. The data centers had been built to handle low power density racks (2-3 KW/rack), and previous performance enhancements had pushed temperatures to borderline conditions. Using CoolitDC analysis, CAS proposed a redesign that prevented uncontrolled mixing of hot and cold air and decreased temperatures throughout the entire room well below the recommended equipment limits.

In this rack application, CoolitDC was used to boost rack cooling efficiency by optimizing air flow. The optimization permitted using warmer incoming air without adversely affecting the cluster cooling, resulting in a sizeable reduction in data center power consumption. Using CoolitDC and optimization methods the designer solved hundreds of cases to determine the optimal rack configuration. The resulting design was 50% more energy efficient than the initial rack configuration.

Daat Research Corp. announces a release of Windows 7 compliant versions of Coolit® v. 10 and CoolitPCB® v. 6 CFD software for thermal design of electronics. The new release includes numerous enhancements that add functionality and increase ease-of-use, the trademark of Coolit software since 1996. The improvements involve all modules: pre- and post processor and the solver. Among important changes is an improvement in the editing speed of very large thermal models, as well as the ability to edit in 3D. Increasingly thermal engineers must model systems with exceptionally high component counts. To meet this need, Daat developed an algorithm that enables objects in large models to be resized and repositioned without the lag normally associated with such changes. Mouse movements are dynamically converted and computed on the fly, allowing models to be redrawn with little delay. Other important enhancements include clipping planes, that enable users "to look inside" a 3-D object as well as two new one-click flow visualizations. The visualizations automatically animate the solution domain showing the evolution of the air flow, the temperature, and other variables. These new features, along with many other enhancements that boost user friendliness and power, are found in Daat's Coolit v. 10, the comprehensive thermal management software for electronics, and in CoolitPCB, v. 6, the company's low-priced CFD package for circuit board designers. Coolit® v. 10 and CoolitPCB v. 6 are shipping now. Both packages operate across all Microsoft-supported Windows platforms. Company Background Founded in 1992, Daat concentrates on the development of top-performing computational fluid dynamics (CFD) products. Its award-winning flagship product, Coolit offers remarkable ease of use, accuracy, low memory requirements, and exceptionally fast solution times that are particularly valuable for design optimization and "what if" analyses of complex problems. CoolitPCB is a highly cost effective and easy-to-use CFD software that enables PCB designers to do their own board level analysis, accurately predict the thermal behavior of their designs and pinpoint optimum component placement. Under the hood is the robust, proven and advanced computational engine, developed by Daat Research Corp. and used on thousands of design projects. Coolit and CoolitPCB are registered trademarks of Daat Research Corp. All other trademarks are property of their respective owners. For more information, visit www.daat.com or email to info@daat.com.

Daat Research Corp., developer of the Coolit® family of CFD thermal and flow analysis software, announces a partnership with RMC Engineering to sell and support Coolit applications in Turkey. The Istanbul-based technology company, RMC Engineering is a well-known provider of CAE products and services to the automotive and defense industries.

Israel-based ECI Telecom designs telecommunication platforms and solutions for carriers, cable and wireless providers, utilities, and government and defense organizations worldwide. For these customers, thermal reliability is critical and ECI depends on CFD analysis to achieve it. In a recent design involving high power mother-daughter board combination housed in a small enclosure densely populated with large vendor modules which blocked airflow, commonly used design techniques proved inadequate. ECI's engineers came up with a new approach: add a heat pipe to draw heat from the components on top of the main card to a heat sink in main card's backplane connector area. The new design was optimized and proved in Coolit.

QLogic, developer of high performance networking adapters, switches and ASICs, uses Coolit to save development time and costs in creating its own products and in satisfying stringent customer requirements. The software acts as an up-front tool enabling engineering to select the appropriate components and optimize air flow before committing designs to production. In a recent design, adequate airflow was available, but high power density at the chip level demanded a custom thermal solution, because air flow impedance requirements made it impossible to use an off-the-shelf heatsink. By running simulations on various heatsink combinations, Qlogic was able to zero-in on a custom design that adequately cooled the chips.

Hidden above the ceiling on Airbus and Boeing airframes, as well as on many business jets, is VT Miltope's 802.11n Multifunction Access Point (nMAP), critical hardware for the aircraft's LAN. The nMAP quietly supports passenger Internet access and wirelessly connects crew systems that monitor and control cabin temperature, meals data, and In-Flight Entertainment (IFE) systems. It also wirelessly bridges the aircraft to airport terminals, transferring maintenance data and crew support information. The hardware sits in stagnant air, relying on natural convection and limited conduction into the aircraft support structure. Coolit's early predictions indicated that, without design changes, the processor, radio cards, and Gigabit Ethernet chips would overheat. Coolit design changes were implemented and tested on prototype hardware. The tests verified that the Coolit predictions were accurate, typically within a few degrees of actual for most components.

At a world renown German research institute, LED-lighting is used to simulate the sun during experiments on plant and animal growth. Because temperature influences the wavelength emitted by the LEDs, they require cold plate to provide a uniform temperature distribution across its surface. Coolit was used to analyze the impact of various design parameters. When the Coolit optimized design was tested, it verified the prediction accuracy and satisfied all the cooling requirements.

Desktop Engineering magazine's editors have chosen Coolit for the distinctive honor of DE's Pick of the Week. The award recognizes Coolit's powerful capabilities that enable designers to carry out the component, board and system level thermal design of electronics. Coolit models significantly increase thermal analysis accuracy and shorten the product development time.

CoolitPCB v.5 dramatically shortens modeling time for engineers simulating complex electronics. The user can build complex IC chip models, using model constructors which guide you from start to finish or pick them ready to go from the expanded IC Package library. A simple mouse click then converts the detailed IC package models into compact resistor models, if desired. CoolitPCB v.5 incorporates two new compact resistor model options: a DELPHI option and a new 14-resistor model option. The DELPHI option, lets you specify a resistor network using DELPHI methodology for generating environment-independent compact resistor models of IC packages. Such models are currently available from many IC package manufacturers. New components, many user interface and graphics enhancements have been added, as well as 64-bit operating system support for CoolitPCB solver and for CoolPlot. For more information, visit www.daat.com or email to info@daat.com.

Coolit v.9 thermal & flow analysis software dramatically shortens modeling time for engineers simulating complex electronics. The user can now build complex IC chip models, using either model constructors which guide you from start to finish, or create them from scratch using basic Coolit building blocks, or pick them ready to go from the expanded IC Package library. A simple mouse click then converts the detailed IC package models into compact resistor models, if desired. Instant conversion, not only from constructor and library models but from arbitrary user-built models, gives Coolit a distinct advantage over other thermal software. Compact resistor models dramatically reduce the computational resources necessary to compute complex models with large numbers of IC packages. Coolit v.9 incorporates two new compact resistor model options: a DELPHI option and a new 14-resistor model option. The DELPHI option, lets you specify a resistor network using DELPHI methodology for generating environment-independent compact resistor models of IC packages. Such models are currently available from many IC package manufacturers. The 14-resistor compact model can be used for converting detailed models built in Coolit. Numerous user interface and graphics enhancements have been added, as well as 64-bit operating system support for CoolPlot, Coolit's graphics post-processor. For more information, visit www.daat.com or email to info@daat.com.

With a powerful Intel chipset (2.53 GHz Intel® Core™ 2 Duo Processor), and full slate of MIL-STD-810F environmental requirements--including 60C ambient operating temperature and sealing from water, sand, and dust the TSC V3-GM45 Rugged Laptop Computer (RLC) is used by the Army in portab le configurations and mounted in vehicles (M1113 and M1068) for strategic field applications. Facing this challenge, VT Miltope performed Coolit modeling very early in the design stages when it was not possible to build prototypes because real hardware such as circuit boards and chassis components were not yet available. Much later, when real hardware was assembled, the component temperatures were measured with thermocouples under intensive application heat loads. Measured values proved to be within a maximum of 3C of those predicted by Coolit.

MCL designs high power RF amplifiers that serve as uplinks in satellite communications systems. Typically, the units operate outdoors and must be environmentally sealed and must be as small and light as possible. Thermal performance versus weight became a real challenge during a recent heatsink development. Higher performance designs created over weight conditions, while the lighter designs did not adequately cool the components. To balance the performance versus weight, MCL enlisted Coolit software. The solution proved to be a combination of materials. Coolit analysis determined the optimal fin shape, size and spacing. It minimized heatsink size and quantified air flow requirements.

Daat Research Corp., developer of the Coolit® family of CFD thermal and flow analysis software, announces a partnership with CMR Design Automation to sell and support CoolitPCB applications across India and South Asia. The well-known consulting firm is one of India's oldest suppliers of Electronic Design Solutions and it services customers in government, industry and education. Its customers include Motorola, Panasonic, National Semiconductor, Infineon , ST, HCL, Wipro, TCS, Microchip Technology and a host of others.

A manufacturer of LCD and plasma TVs could not squeeze an adequate heat sink into the space available around a critical 37 watts processor. A solution with a heat pipe conducting heat from the processor to a remote heat sink. With the aid of Coolit, the heat pipe diameter and routing, heat sink parameters, interface materials, and the vent configuration were optimized. Subsequent physical prototype testing confirmed Coolit predictions to within 5% of the actual component case temperatures.

Desktop Engineering magazine's editors have chosen CoolitPCB v4.0 for the distinctive honor of DE's Pick of the Week. The award recognizes CoolitPCB's powerful new capabilities that enable designers to construct detailed and compact models of IC packages. The resulting models significantly increase thermal analysis accuracy and shorten the model development time.

The introduction of CoolitPCB v 4.0. heralds a powerful new thermal modeling option for PCB designers. Users can construct detailed models of Ball Grid Arrays (BGA), Dual Inline Packages (DIP), and Quad Flat Packages (QFP), or alternatively, select IC packages from hundreds in the new IC Packages Library, modify them and save the results. With just a click, the models can be converted quickly into compact models for faster rapid computation. "Detailed models boost the accuracy of thermal analyses, but IC data is often difficult for designers to obtain," explains Daat's President and CTO, Arik Dvinsky. "With this CoolitPCB v4.0 option, designers have the information at their fingertips." "The new option is a big time saver when analyzing PCBs," notes Elias Debs, thermal engineer at EMS Technologies Ltd, Ottawa, Canada. "Previously you had to search the IC supplier's website and, sometimes, the data wasn't even there. Then you could easily make an error transferring the data into your model. With the new CoolitPCB option, you just select the component and run the analysis." CoolitPCB v4.0 is a highly cost-effective and easy-to-use CFD software that enables PCB designers to do their own board level analysis, accurately predict the thermal behavior of their designs and pinpoint optimum component placement on their boards. Under the hood is an advanced computational engine proven in thousands of design projects. For more information, visit www.daat.com or email to info@daat.com.

Equipment designed to military specifications faces extreme environmental conditions, and in the case of one Tablet PC, it included being waterproof and operating in 70 deg. C ambient. The manufacturer initially designed the ruggedized system as a sealed enclosure containing a CPU board, pc board, two batteries, hard disk, touch screen, speakers, GSM module and finger print sensor. With the aid of Coolit, the heat sink geometry and placement of the heat sinks, vents, fans and ICs were optimized without building a single unit, saving the client thousands of dollars in prototyping and testing costs.

Coolit introduces powerful new tools for IC package construction in its latest release, v.8. The new tools permit semi-automated building of detailed chip models for several classes of IC packages. The detailed models can be used as is or converted to compact models using several offered compact model options and the user can switch back and forth between detailed and compact models as desired. In addition, a library of hundreds of popular IC packages is included. The user can add new IC packages to the library or copy and modify the existing entries. Coolit v.8 also delivers many improvements in algorithms for computation and presentation of results. Further enhancements to Zonal Grid calculations have been made including the removal of most restrictions on Zonal Grid placements. These and many other enhancements make Coolit even more user-friendly and powerful to use. For more information, visit www.daat.com or email to info@daat.com.

CFD thermal analysis software is freeing engineers to create smaller, more reliable boards and systems, while simultaneously reducing development time and costs. The software solves the partial differential equations that describe airflow and heat transfer and presents results as 3D color-coded images that show thermal and flow conditions in a modeled system. Airflow and temperatures can be overlaid to show their interaction. Several applications including a rectifier, powers supplies, air conditioning, etc. are mentioned. Click "Full Text" below and go to pp. 40 to read the article.

EMS SATCOM, Canadian developer of wireless, satellite and defense communication systems, uses CoolitPCB to optimize heat sinks. Since heat sinks frequently drive enclosure size and weight, the results lead to smaller and lighter packages. To verify CoolitPCB model predictions, EMS built and tested physical prototypes in a lab under both air cooled and failed fan conditions. In all cases, CoolitPCB predictions matched actuals to within 5%.

Daat Research Corp. introduces the power of parametric model construction in its latest release, Coolit v.7. Using this new option, the user selects the desired project objects, defines their parameters and generates the cases to be solved. Optimum designs can be determined quickly by adjusting the model parameters and re-running the cases. Coolit v.7 also incorporates significant improvements in presentation and rendering of non-rectangular objects. Additional enhancements include new algorithmns for faster and more robust Zonal Grid calculation, faster Fluid Region calculation, a new non-linear flow resistance option for porous media objects, the new Solar Radiation dialog, tracking and synchronizing library with model object, better reporting, plus many other features that make Coolit even more user-friendly and effective to use. For more information, visit www.daat.com or email to info@daat.com.

IBM's Boeblingen, Germany Development and Research Site develops very densely packed blade servers, often having several new systems and performance enhancements in development simultaneously. Each server consists of a high density pc board for which optimum component placement, particularly of processor chips, power supplies and switches, is crucial to cool operation. Designs originate with the architects, who previously had to wait in queue for thermal analysis assistance from the mechanical engineering department. To eliminate these delays, architectural engineering began doing its own CFD analysis, using CoolitPCB. Boeblingen Lab is now catching potential thermal problems earlier, reducing development time and bringing new products to market faster.

CFD software is an invaluable thermal-analysis weapon for the electronics design arsenal. At VT Miltope Corp. in Boulder, Colo., it saves weeks of development time and thousands of development dollars-even on small projects. A CFD simulation presents a window into an electronics design, enabling an engineer to pinpoint hot spots and follow air across a board or through a chassis. The analysis predicts temperatures at every point, including points that are physically impossible to measure. Sometimes, an engineer believes he intuitively “knows” how cooling air might flow or where the hot spots will crop up, only to encounter unexpected eddy currents, fans and vents that are poorly located, or heat sinks that are undersize. CFD analyses eliminate this guesswork and delivers predictions accurate to within 10 percent or better.

Daat Research Corp, Hanover, NH is celebrating 15 years since its founding in 1992. What began as an R&D company providing CFD software development services for the industry and the government has transformed into a leader in CFD thermal design software for electronics. "When we began, most engineers were intimidated by CFD's complex mathematics," notes Daat's Marketing Manager, Peggy Chalmers. "As a result, they missed out on CFD's ability to slash development times and costs." Daat scored a break-through by implementing the first Microsoft Windows-based intelligent user interface into its flagship software, Coolit. Suddenly, CFD became easy-to-use for non-experts, and running on inexpensive PCs. Coolit quickly became the standard for industries from Aerospace and Autos to Communications and Entertainment Electronics. Daat's latest product, CoolitPCB, uses the same approach, making CFD readily accessible to PCB designers. Using CoolitPCB, electronic engineers can accurately predict the thermal behavior of their designs and pinpoint optimum component placement. In addition to its products offerings, Daat delivers a range of thermal and fluid flow consulting services.

St. Isaac's Cathedral in St. Petersburg is considered one of the most beautiful churches in the world. The church reveals a breathtaking interior encrusted in gilt bronze, marble and rare stone, stunning mosaics and columns of pure malachite and lapis. But historical and artistic significance has not kept the Cathedral and its contents from slowly crumbling. Nearly two hundred years of widely oscillating temperatures, leaky windows and doors, and uncontrolled humidity have taken their toll. To save this national treasure, the city of St. Petersburg is planning to develop a HVAC system to halt further deterioration. In initial phase of the project, the municipality contracted with St. Petersburg Polytechnic Institute and New Technology and Services Ltd to develop a computer model of the building to make a quantitative assessment of the airflow and thermal conditions within the cathedral.

When developing mission-critical equipment, military contractors demand quick reliable answers to thermal problems. Byrd worked with power supply manufacturer, Granite Power Technologies to develop a vehicle-based power supply headed for Iraq. Coolit analysis predicted that the supply was within its thermal design limits. To access the accuracy of the model, it was compared with a lab experiment. The prediction and actuals came within 1 deg. C.

For a major Boeing avionics upgrade to the Air Force's C-130 aircraft, VT Miltope developed a digital mass storage system to collect high-speed digital map and ground terrain data. The system consists of a chassis-mounted processor, high speed interface and sealed, removable hard disk drive. Design requirements specified 10.1 psia air pressure and steady-state operation at 55 deg C with short-intervals up to 71 deg C. For operator safety, equipment surfaces could not exceed 11 deg C above ambient air temperature.

Desktop products present a tough thermal challenge for design engineers. Small footprints concentrate heat and leave scant space for air circulation. Crowded electronics make it tough to instrument and find hot spots. Traditionally, effective thermal solutions for electronics could only be developed through a long round of building, testing, modifying, and retesting. At Seagate’s Design Service Center, Coolit CFD thermal and flow analysis software from Daat Research Corp. is used to solve a wide variety of thermal problems for their desktop OEM customers. Seagate engineers modify designs with just a few mouse clicks and calculate results in a fraction of the time it would take to modify and test physical prototypes: No hassle and no waiting for the shop to cut or bend metal.

Coolit, the popular and powerful thermal and flow analysis software, delivers an impressive list of enhancements in its latest release. V6.0 delivers expanded CAD import capabilities, slashes the time required for fine grid calculations, adds multiple fluid domains within an enclosure and is 64-bit ready. In addition, there are numerous ease-of-use and reporting advancements. These features are outgrowths of Daat's on-going enhancement program for the world's easiest-to-use and most powerful thermal software. Coolit v6.0 expands its CAD file import capabilities with the addition of STEP files, and also delivers an improved import user interface. With v6.0, there is no time penalty for performing fine grid calculations. Coolit has incorporated a new zonal grid that delivers the accurate temperature prediction with fine meshes in virtually the same time it would take for a coarse grid calculation. The new release incorporates a capability to define different fluid domains within an enclosure. As many fluid domains as desired can be added, each containing a different fluid. This functionality is especially valuable for modeling systems with liquid cooling. Coolit v6.0 will import PCB artwork (traces), a feature that allows engineers to quickly and simply perform board level analysis. The ability to simulate traces is found in no other CFD software. The new release offers numerous time-saving features in its dialogs, report, viewing, component modeling and error reporting. For more information, visit www.daat.com or email to info@daat.com.

In the Airbus, the power supply for the air-conditioning controls is cooled by the very system it controls. The IGBT module's is built without conventional base plate such that IBGT chips and power diodes are mounted directly to the die cast housing of the turbine that circulates conditioned air throughout the cabin. Heat is conducted through the housing to stator blades that are immersed in the air drawn through the turbine.

To maximize module count while minimizing footprint, Honeywell engineers developing the Experion R300 process control system vertically stacked the I/O and Controller modules. But vertical stacking created an overheating problem. Cool air entering the bottom of the cabinet would grow warmer as it traveled upward from one module to the next. By the time it reached the upper portion of the stack, the air would be so hot that it would cause modules to overheat. To solve this problem, Honeywell engineers created a slanted module design that delivered unheated air to each of system modules. The approach was validated using Coolit, saving hundreds of thousands in test dollars.

CoolitPCB, the price shattering CFD software for board level analysis, is delivering major new functionality in its latest release. Now shipping, V2.0 simulates traces, a feature unique for CFD software. The user can import board artwork directly for thermal analysis. Priced at $4900 perpetual license, CoolitPCB costs only a fraction of would-be competitors. Yet there is no sacrifice in power, performance or accuracy. Already well-known for its unprecedented ease-of-use, CoolitPCB enables both electrical and mechanical engineers to perform accurate CFD analysis with ease. An intelligent user interface steers the user effortlessly through solution process. No training is required. CoolitPCB is fully integrated with Daat Research's flagship thermal design software Coolit, so board designs can be readily incorporated into system level analysis. For more information, visit www.coolitpcb.com or email to info@daat.com.

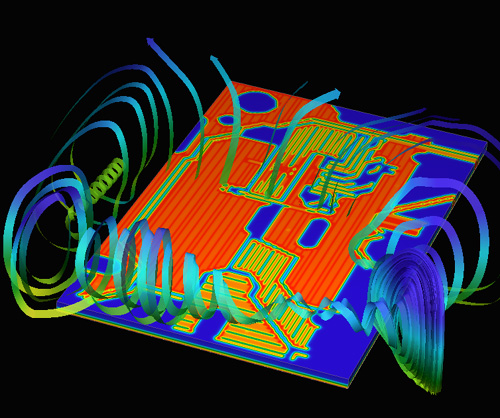

Board artwork can be imported directly for thermal analysis in CoolitPCB v.2.0. (Courtesy of Siemens AG.)

Canadian electronics manufacturer, Filtran is using CoolitPCB to design ruggedized power supplies for a major military telecom application in which ambient temperature pushes against the upper design limit of the components. Because little margin is available, accurate thermal analysis is crucial.

After prototype testing verified Coolit predictions to be accurate within 5%, a major German developer of surgical and medical aesthetic lasers used Coolit to optimize its TEC-cooled designs. Munich-based thermal consultant, AMS Technologies AG, performed the analysis by combining arrays of TECs into Coolit models. The pumping power of the individual TECs, the coefficients of performance, the temperature distributions and thermal resistance of the heat sink were obtained and available for optimization. The results also were used to establish selection guidelines for the laser diode modules.

Aided by Coolit, Calgreg is saving its customers money and building the kind of customer relations that result in repeat business from satisfied buyers. The heat sink manufacturer, who services a spectrum of industries, creates custom designs that are frequently better than what the customer asks for.

Seagate, a leading manufacturer of data storage equipment, prides itself on the reliability of its hard drives. Using Coolit, Seagate engineers completed the project in a fraction of the time. Multiple design scenarios were analyzed in less than a week and an optimized thermal design was delivered without building costly prototypes.

ADVA AG, the leading metro optical-networking provider in Europe, develops a fiber optic and optoelectronic boards, and the accompanying cabinets and shelves. The company had tested other thermal packages, but found them cumbersome. Using Coolit, they were able to easily construct and run models, and display the three-dimensional colored simulations that predict temperatures and airflows inside their cabinets.

Excessive heat can destroy electronic systems. Although designers know that mitigation strategies such as heat sinks, fans, diverter fins, and conduction cooling solve temperature challenges in chassis enclosures, too often designs are based upon “best practice” or even trial and error. Today, computational fluid dynamics simulation discovers optimum thermal solutions before troubles occur. Additionally, “what if” software aids designers in making trade-off decisions.

New, powerful and highly affordable CoolitPCB frees PCB designers to do their own board level thermal analyses. EEs now can accurately predict the thermal behavior of their designs and pinpoint optimum component placement on their boards. There is no need for expert knowledge of heat transfer or CFD; CoolitPCB's intelligent user interface steers the user through the solution process. But users shouldn’t be fooled by this simplicity. Under the hood is the robust, proven and advanced computational engine, developed by Daat Research Corp., that has been successfully used for hundreds of design projects. At $3900 for a perpetual license, CoolitPCB costs a small fraction of competing tools, yet there is no compromise in functionality. The software will enable the import of board designs from CAD and EDA software, perform testing for standard JEDEC forced, free convection, slots as well as custom setups. In addition, it will report component junction temperature, case temperature, as well as detailed 3D airflow and temperature distribution. CoolitPCB is fully integrated with Daat’s flagship thermal design software, Coolit, so optimum board designs can be readily incorporated into system level analysis. For further information, contact Daat Research Corp at: info@daat.com. Initial deliveries of CoolitPCB will begin in August.

Выговорите по-русски (Do you speak Russian?). Well, maybe not, but the Russians are speaking Coolit. A group of distinguished professors at St. Petersburg Polytechnic University selected Coolit, from among existing commercially available packages, to be the basis of a new course on computer-modeling tools for students of hydrodynamics, aerodynamics and heat transfer. Coolit was chosen because of its winning combination of accuracy, ease-of-use, and power. The course development, funded by the Education Ministry of the Russian Federation, resulted in a six month evaluation of available software which left the Russians impressed with Coolit's unique capabilities and remarkably intuitive user interface which allows students to concentrate on problem solving, not learning software. The comprehensive course requires no previous numerical modeling or CFD background, so it is suitable for all levels of students and designers. In order to elucidate the underlying physics, it begins with deriving the mathematical models of fluid mechanics and heat transfer. Considerable attention is paid to turbulence modeling. The course then covers numerical methods for solving the derived equations and wraps up with Coolit modeling of real life thermal problems. The course textbook is currently in print at the OKDAIL Publishing House in St. Petersburg. It is expected to be available in July ready for the new academic year.

Daat Research Corp., developer of the innovative Coolit ® CFD thermal and flow analysis software, announces a partnership with consulting firm, Waveaxis to sell and support Coolit applications across India. Located in Bangalore, the Silicon Valley of India, Waveaxis is recognized for its thermal design work within research establishments, electronics design houses and among manufacturers of electronics equipment. The company has extensive experience in delivering solutions to the telecommunication, avionic, automotive and industrial sectors.

Daat Research Corp., creator of the award winning Coolit R CFD thermal analysis and design software has joined forces with CE Technologies Ltd., the highly respected thermal management consulting firm based in the UK. Under the newly formed alliance, CE Technologies will become a licensing agent for Coolit CFD software and provide technical support for Coolit customers in Europe.

Thermal engineers trying to force a few extra watts into their ever smaller thermal designs, will find a powerful new tool in the new version of Coolit. Dr. Eldad Levy of CAS Ltd. was recently able to save nearly a week's worth of work and thousands of dollars by using Coolit's automatic design optimization module, OptimizeIt, to bring a telecom chassis design to within spec. Machine Design magazine interviewed him on his experience.

CAS Ltd, recently designed a telecom chassis for telecom manufacturer, Actelis Networks. The chassis was a 1U configuration (1.75 inches high) and 9.5 inches wide, dissipating approximately 35 W. The initial design had several key electronic components at, or exceeding their manufacturers' limits. CAS used Coolit's new OptimizeIt module to optimize fan type, fan location, and the number, sizes, and locations of the vents. With the design OptimizeIt found, the BGA temperature dropped from 96 deg. C to 88 deg. C, while the case temperatures of the circuit side components fell from 95 deg. C to 89 deg C.

Honeywell, a leading provider of integrated avionics, was able to save months in prototyping and testing on a recent chassis design by using Coolit. Thermal and electrical engineers were able to reach compromises in thermal design and EMI protection early in the development process. Coolit provided the engineers with grounds for adding more vents to the enclosure before building the first prototype. Thermal engineers were also able to save prototyping time by using Coolit to help them optimize cooling fin placement and geometry.

When performing thermal analysis, signal-processing leader Applied Signal Technology Inc. overcomes its manpower limitations with a combination of Daat Research's consulting services and their own in-house expertise. Recently, Daat's thermal expertise was tapped for schedule-critical modeling of a 19-inch data acquisition chassis. Daat consulting created the base model, while Applied Signal engineers performed design optimization. The Coolit analysis pinpointed hot spots in the design and saved an estimated 4 months in prototyping.

Hanover, NH - April 8, 2004 - Daat Research Corp. announces a powerful new tool, OptimizeIt, that makes design optimization faster, more effective, and more efficient. An integral part of the newly released Coolit v5.55 thermal and fluid flow simulation software, OptimizeIt can be used for assessing a system's sensitivity to design variations, and for optimizing system design

Analogic Corp., Peabody, MA, whose data acquisition systems are found in approximately three quarters of the world's Computed Tomography (CT) equipment, depends on CFD analysis to handle the unique thermal problems posed by its CT applications. In its latest design, the company used Coolit CFD thermal and flow analysis software from Daat Research Corp. to select and size the appropriate forced air device, design a baffling configuration and equalize airflow across multiple data acquisition boards.

Powerware, a leading global provider of comprehensive power quality and backup power management solutions, faced stiff design restrictions in producing its new Intergy R3048 rectifier module. The 3 kW unit would dissipate 300 W, and in order to achieve balanced three-phase currents, units had to be mounted in multiples of three per 19-inch wide shelf. This meant the rectifier envelope had to shrink by at least 50% over the existing model. To quickly scope the problem, Powerware design engineers enlisted Coolit which helped design a tiny, but highly effective heat sink with optimized fin spacing and pinpointed preferred fan and vent locations. The optimized unit shrunk to roughly 60% of the original size, enabling six units to fit within a 19-inch shelf. Plus, the rectifier's power density exceeded 10 W/in3 - making it the most power dense 3kW rectifier available.

Embedded mesh technology adds impressive capabilities to CFD (computational fluid dynamics) thermal and flow analysis for electronics cooling. It simplifies model building while increasing model fidelity and accuracy. It dramatically reduces cell counts making it possible to model complex systems and boards that were impossible to model before. It eliminates dependence on approximate model building techniques, such as resistor networks and lumped parameter (compact) models. And it significantly reduces calculation times over existing approaches. The embedded mesh technology implementated in Coolit v5.0 from Daat Research Corp., Hanover, NH, was benchmarked for this article to evaluate benefits of the new technology.

Hanover, NH - August 27, 2003 - Daat Research Corp., creator of the award winning Coolit® CFD thermal analysis and design software has joined forces with AMS Technologies AG, a leading European supplier of high tech, thermal management components, systems and services. Under the newly formed alliance, AMS will become a licensing agent for Coolit CFD software and provide technical support for customers in Germany, Italy, Spain, Switzerland, Austria and the UK.

SLAC (Stanford Linear Accelerator Center) and NASA are building the satellite that will transport to outer space the 'grand observatory' for mapping gamma-ray bursts. This telescope known as GLAST, acronym for Gamma-ray Large Area Space Telescope, will deliver 50x the resolution of the existing EGRET project and will probe the mechanisms of particle acceleration, investigate dark matter and the early Universe, and advance science's knowledge of black holes. To verify the system's thermal design across the full temperature spectrum, SLAC enlisted Daat Research Corp. consulting services. Utilizing Coolit, Daat proved that the SLAC-designed system would handle even the worst-case conditions.

With each product generation, American Power Conversion (APC), a leading manufacturer of uninterruptible power supplies and power management products, has found itself fighting tougher thermal battles. Users demand higher power, but smaller units, a combination that creates higher heat loads. Shrinking packages have made it challenging to effectively locate fans and vents; correct component placement often proves counter-intuitive, and the resulting airflow problems can trip up even experienced thermal engineers. Faced with increasingly complex thermal problems, APC added Coolit CFD program to optimize product performance. As the design evolved, Coolit became the arbitrator between electrical and thermal engineering. When electrical engineers questioned the model's validity, the thermal engineers pointed to the excellent agreement between Coolit predictions and physical testing. Experiments had shown that a 5-10% temperature change in the Coolit model produced an equivalent change during testing. Throughout the project, Coolit eliminated trial and error and uncovered problems without prototype testing. By the time the project was completed, Coolit had reduced time from the design schedule and helped APC introduce a much improved design.

With the release of version 5.00, Coolit incorporates embedded mesh technology. This pioneering approach eliminates dependence on approximate model building techniques, such as resistor networks and lumped parameter (compact) models, thereby simplifying model building while increasing model fidelity and accuracy and delivering order of magnitude increases in calculation speed. When solving the partial differential equations that govern the flow of fluids and heat, engineers use a grid (mesh) to split the domain into a set of control volumes (cells) tailored to the size, shape and physics of that particular space. Components with fine details or dimensions require correspondingly small grid cells, while larger, slower changing spaces suffice with larger cells. Since an abrupt transition from small to large cells can cause major accuracy and stability losses, extra grid cells must be added to modulate the transition. High accuracy also demands numerous small cells, slowing down the calculations and requiring more computer memory. Once the cell count gets too large, it can overwhelm even the most powerful workstation. Most commercial CFD programs will choke on well under one million grid cells. To avoid these problems, engineers resort to sub-modeling for complex systems. They create models within models, replacing some subsystems with simplified models based on lumped parameters (compact model) or resistor networks. Defining these submodels is a formidable task, and a model developed for one environment will not work in another. With the introduction of embedded mesh technology, Coolit v5.0 eliminates the guesswork associated with standard submodeling techniques. The software creates individual mesh systems for objects within the system using a grid setup based on the length scales and the physics of each zone. Other changes in the new release included improved CAD import, new smart components, and enhanced flow visualization and AVI file creation. All new Coolit v.5.00 features are available, at no extra charge, with purchase of a basic Coolit license and as free upgrades to existing license holders. Coolit v.5.00 operates on all Windows-based platforms: Windows 95, 98, NT, 2000, and XP.

When one of its telecommunications systems underwent a major revision, Lucent enlisted Coolit to determine the impact on thermal performance. The new board design had dramatically boosted power levels on certain components and required six new custom heat sinks to cool. Using Coolit, the company successfully optimized these heat sinks, without relying on costly prototypes. Modeling the system with over ten heat sinks with fins as thin as 0.008" (0.2 mm) proved complicated and porous media models of heat sinks were used to keep design iterations within one day. However, developing porous media models required time and as always with lumped parameter models it resulted in a loss of detail. The problems of lumped parameter models have been eliminated with the new embedded mesh technology in Coolit v5.0. The new technology enabled the modeling of all heat sinks and other components without any approximations thereby eliminating the time required to build compact models of components, while increasing the model fidelity and hence predictive accuracy and delivering order of magnitude increases in calculation speeds. Revisiting the Lucent design using embedded mesh technology resulted in about 4 hours per iteration (vs the original 24).

With the introduction of embedded mesh technology, Coolit has dramatically reduced cell counts making it possible to model complex systems and boards that were impossible to model before. It has eliminated dependence on approximate model building techniques, such as resistor networks and lumped parameter (compact) models. And has significantly reduced calculation times over existing approaches. CAS Ltd. compared the impact of embedded mesh technology on two projects. In both applications, Coolit easily resolved the multi-scale models accurately without resorting to approximations, such as lumped parameters. The length scales ranged from almost a meter (chassis size) down to a micron, all within the same model, a feat not possible with other CFD software.

Product Design and Development magazine has announced that its editors have chosen Coolit as a finalist in its Annual Engineering Awards program that salutes most significant ideas showing innovation, creativity, and usefulness to society. Coolit was recognized for its pioneering contributions to CFD technology making it accessible to ordinary design engineers and to occasional users and enabling them to develop accurate, reliable, and cost-effective cooling solutions and to shorten development cycles.

An article published in this month's COTS Journal details the thermal design process of a ruggedized laptop for the US Army. Miltope Corporation used Coolit early in the design process to catch any thermal problems before building prototypes. Specifically, they determined that several components other than the central processor and video processor required heat sinking. This "save" by Coolit made the difference between meeting and missing the deadline for Miltope.

CAS Ltd. developed a thermal design for a Lucent Technologies communication system, replacing a failed design provided by a consulting company. The consultant had predicted that no heatsinks were required on the system's optical modules. CAS, using Coolit, determined that just the opposite was true, and prototype testing proved that the Coolit analysis was correct.

In a project sponsored by Axxion Corp., a major manufacturer of personal computer enclosures and chassis, researchers at the University of Texas used Coolit to analyze the impact of various ventilation configurations on airflow within a desktop computer chassis. By creating the simulations, the researchers were able to improve the chassis design without building physical prototypes.

Miltope Corp. had only 3 months to go from design to production on its mortar fire-control computer system for the Army. The extremely tight schedule meant almost no time for building physical prototypes to measure temperatures as a check on heat buildup inside the system electronics. So Miltope enlisted Coolit to develop a rugged, passive cooling design, confidently eliminating physical prototyping and thereby shaving 25% off the development cycle. Production units sailed through formal environmental qualification testing, as well as recent early field trials.

ITT Gilfillan used Coolit to predict the thermal performance of new parts for its air defense and air traffic-control radar systems, saving months of prototype testing. Detailed models of its new systems have led to more robust designs with optimal performance. Coolit has greatly reduced product development costs and helped avoid schedule delays.

Daat Research Corp. has added multiple processor capabilities to boost the calculating speed of its CFD thermal and flow analysis software, Coolit. When installed into a multiple processor system, Coolit automatically recognizes the number of processors and parallelizes the computation accordingly. The result is a significant speed increase that ranges from a minimum of 1.5 times to almost double for dual processors. For more processors, speed gains are even greater. Coolit v. 4.50 also adds new shapes to the component library. Tetrahedron, pyramid and spherical cap components join the previously released triangular prism components to make possible more complex shapes and more accurate geometries. Click here to see an example simulation with some of the new components. Other changes in the new release included greater editing flexibility, a wider range of component characteristics, and customizable projections in panel views. Coolit v. 4.5 also implements a new advanced model for porous media. The new model is a significant improvement over the standard Brinkman model, which is used in most commercial CFD programs. All new Coolit v. 4.5 features are available, at no extra charge, with purchase of a basic Coolit license and as free upgrades to existing license holders. Coolit v. 4.5 operates on all Windows-based platforms: Windows 95, 98, 2000, XP and NT.

Coolit is Varo's 'Early Warning System', pinpointing problems so that electronics designers can make quick design changes. Under a recent contract to Lockheed-Martin, Coolit helped Varo develop a digital power supply for the Apache helicopter's Arrowhead Project, a fully modernized night vision and target acquisition system. It took less than 4 hours to load the software, run the tutorials, perform some test simulations and then begin running actual design scenarios. Coolit proved to be much easier-to-use than other CFD software we tried. Coolit also was priced lower than its competition and offered impressive stability. Throughout the project, we had access to Coolit's excellent technical support.

In this benchmark experiment, CAS Ltd. designed and built a cooling system for a 250-watt computer, to be installed on an aircraft. The computer's exterior was cooled by natural convection and radiation. The chassis interior was cooled by forced airflow through a plate fin heat exchanger installed on both sides of the chassis. The system was designed using Coolit and a system prototype was built to Coolit predicted specifications. The predicted pressure drops across the heat exchanger for different mass flow rates representing the different flight conditions were than compared to experimentally measured pressure drops. The benchmark also compared actual temperatures with the predicted values at one of the design mass flow rates. The results of this study can be viewed in Applications Gallery by clicking the link below.

To cope with soaring Internet traffic, Montreal-based Hyperchip Inc. is developing Internet routers that push data 1000 times faster than existing units. Hyperchip's petabit (trillion bits per second) units are raced to market under an accelerated development schedule that allots a mere 9 months from concept to working prototype. The aggressive schedule was made possible by using CFD prototyping with Coolit. Hyperchip estimates that without Coolit, at least 3 months would be added to the schedule.

Tality, a Cadence' subsidiary, built a telecommunications system for a major client based on the CFD model built in CFdesign by a PhD consultant. Unfortunately, the analysis failed to predict key flow features that were discovered in the prototype and which caused the system failure. Facing tight deadlines and complex system which had to be redesigned, using prototype testing was out of the question. Turning to Coolit, touted as the world's easiest CFD software, Tality hoped that it would also be accurate and fast. It was. Coolit required only two hours total to solve the problem: one hour to model the entire system and one hour to run the calculations. The computed airflow matched the prototype data both for the airflow pattern and velocities to within a few percent. Within two weeks, one Tality engineer running two copies of Coolit optimized the design with over 75 CFD simulations. Follow-on prototype testing verified that the Coolit predictions did, indeed, match the real life results.

At telecommunications equipment manufacturer, General Bandwidth, tight production schedules make rapid thermal prototyping imperative. To perform design iterations, General Bandwidth enlists Coolit's fast solver. Prior to this, General Bandwidth depended on an outside consultant for its thermal analyses. Ramp up for the in-house three member team occurred rapidly and Daat Technical Support was there to help as required. Since they began using Coolit, General Bandwidth has significantly shortened its thermal prototyping schedules and saved thousands of dollars in consulting fees.

Thermal engineers often have to deal with optimization problems, such as finding a minimum size or weight of a device without reducing its performance. Mathematically, this involves finding the minimum of an objective function under specified constraints. Standard optimization procedures don’t work well in thermal CFD due to the large number of solutions necessary, each of which could take hours. In this article a practical approach to engineering optimization problems is described which relies on Coolit’s parametric design tools and fast solver.

Hanover, NH...Coolit, the world's easiest-to-use thermal analysis software for electronics, announces the availability of hybrid meshing, a first for CFD (computational fluid dynamics) software. Hybrid meshing delivers the geometric flexibility of unstructured grids, without their negatives of slow convergence and poor stability. It handles non-rectangular objects automatically and with ease, permitting users to build realistic and accurate models of complex geometries. Coolit v. 4.0 delivers up to 30% faster solver performance due to improvements in the solution algorithms, and it incorporates several new features that enhance ease-of-use and analysis flexibility.

NEC designer provides a detailed review of Coolit from the moment he received the software through initial ramp up and finally its application to heat sink design. He reports that it took a half day from the moment the software was installed to the time they built and analyzed their first heat sink model. His first Coolit project---a heat sink for network servers---was completed in one-tenth the normal time and at a per piece price reduction of 80%. Initial iterations ran for less than an hour on a dual Pentium III, 600 MHz PC with 512 Mbytes RAM, while the computer handled other engineering work in parallel.

"Significant innovation" ----that's what Control Engineering editors call Coolit CFD software. The editors of Control Engineering, a Cahners Business Information publication, selected Coolit, from among the thousands of products they review each year, to become one of 40 recipients of the magazine's prestigious Editors' Choice Award. Selection was based on three criteria: technological advancement, market impact and service across more than 60 industries.

Miteq has been using Coolit to minimize prototype building and testing, reduce cost and time to market and to increase thermal performance and reliability of its products. In this project a rack mounted SSPA (Solid State Power Amplifier) was designed using Coolit. Correlation between the Coolit thermal model and actual data obtained from the physical prototype has been excellent. Measured results have been within 5% of what the Coolit model has predicted.

Honeywell realized engineers could get quick and accurate answers by applying CFD thermal analysis software to give them a window into the thermal and airflow conditions within their designs. CFD would rapidly calculate "what if" scenarios and enable them to pick the best case configuration in a fraction of the normal design time. More accurate answers meant fewer prototype passes. In some case, prototypes could be eliminated entirely, dramatically slashing development time. To select the CFD tool that best met the company’s requirements, two engineers were assigned to evaluate the major vendors. After putting the packages through their paces, they recommended Coolit.

Seagate uses Coolit to provide valuable feedback to consumer electronics customers. In many cases, analysis is done on designs prior to any prototype builds. Feedback is given to the customer on expected drive temperatures and design changes are suggested that increase thermal performance. This approach provides optimal thermal designs, reduced cost and time to market, and increased overall system performance and reliability.

Hanover, New Hampshire---July 1, 2000--- Daat Research Corporation announces Coolit v3.5, CFD software that can directly import PRO-E models for airflow and thermal analysis. Part or system geometries can be transferred to Coolit, eliminating the need for IGES or STEP tranaslation. Thermal and fluid properties of materials are specified directly in Coolit. Coolit v3.50 is available on all Windows platforms-- Windows 95, 98, 2000, and NT.

Industrial design/mechanical engineering firm, Design Edge was contracted by chip manufacturer AMD to design an eye-catching PC enclosure that had to be super small, super quiet and delivered ASAP. Super small and super quiet meant there was little room for heat-dissipating components and fans, while the tight schedule ruled out the traditional approach to thermal analysis using prototype-build, test, modify and retest . CFD software was the only way to squeeze thermal analyses into an acceptable schedule, but Lisa Sura, Director of Product Development knew CFD software was expensive. She needed a package that would do the job at a price her small firm could afford. After an Internet search of available offerings, Sura discovered Coolit, the CFD tool geared specifically toward electronics applications. Using Coolit the Design Edge team was able to incorporate changes before the initial design was even tooled, eliminating costly retooling charges. The final PC package is a futuristic design that attracts attention with its very un-PC-like looks. Tiny, quiet, and cool, the spiffy enclosure arrived on schedule thanks to the time savings and thermal visualization power of Coolit.

When NEC Computers Inc., Boxborough, MA tapped Coolit to accelerate custom heat sink development for its new dual processors servers, it landed an added and unexpected bonus-a breakthrough in heat sink design. The seeds were sown as NEC engineers analyzed Coolit models of airflow movement and heat dispersion across elliptical pin fin designs. A conventional elliptical pin fin design maintains a uniform cross-section across its surface. Yet the animated Coolit models were clearly revealing that cooling surface requirements were increasing as air transversed the heat sink. To NEC engineers the fix was obvious: reject conventional topographies and design heat sinks that match the changing thermal demands. The unorthodox design shaves 15 deg. C off processor die temperature and cuts the per-piece cost by over 80%. On top of these bonuses, NEC engineers still reaped the original benefits they sought from Coolit: weeks of savings in design, model building and testing time worth thousands of development dollars.

Specialized computational fluid dynamics or CFD software provides a wide range of capabilities for computer prototyping of electronics in enclosures. Putting the latest CFD technology to best use takes practice and unavoidable mistakes. The problems here are solved with software called Coolit from Daat Research and the following guidelines have been compiled from observations of new users. Learning from their mistakes may shorten your learning curve.

In a ceremony starting with a briefing in the White House followed by a reception on Capitol Hill, Daat was awarded 1999 National Tibbetts prize for its cutting edge research in the area of computational fluid dynamics (CFD), which significantly advanced state-of-the-art for performance of CFD algorithms.

Hanover, New Hampshire --- September 28, 1999 --- Daat Research Corporation, a leader in Windows® software for thermal management of electronics, announced the availability of a direct interface for import of SolidWorks models to its main product, Coolit. The import of the SolidWorks model is available from the "File/Import" SolidWorks menu in Coolit. The import module will then open the desired SolidWorks part or assembly and transfer the geometry to Coolit. The designer can then create a simplified configuration for thermal analysis by suppressing all non-essential detail. This will reduce the size of the resulting thermofluid model and speed up the analysis process. Thermal and fluid properties of materials are specified directly in Coolit.

NASA Glenn (formerly Lewis) Research Center nominated Daat Research for prestigious Tibbetts Award which is given annually to firms, projects, and individuals judged to exemplify best in innovative research achievement. In the course of several NASA funded projects, Daat has conducted cutting edge research in the area of computational fluid dynamics (CFD), which significantly advanced state-of-the-art for performance of CFD algorithms. In one of the projects, Daat developed a superfast CFD solver combined with a genetic algorithm optimizer. The software automatically computed the optimal configuration for the modeled device according to the user-specified optimization objective and variable parameters of the device. Based on this research, Daat developed the Coolit CFD software for electronics cooling applications. Coolit has set new standards for CFD both in terms of speed and quality of its user interface. It is currently the fastest growing CFD software on the market taking approximately 15% market share since its launch in 1996.

Teradyne Corp., the world’s leading automatic testing equipment supplier, has been using Coolit to optimize the thermal performance of new designs. The software permits designers to zero in on best cooling schemes without building costly physical prototypes. In this instance, when a problem appeared in an older power supply already in production, the company decided to use Coolit to ascertain the effect of an external design change on the internal thermal behavior without having to tear the system apart. The problem surfaced in the field when the surface personnel were installing a replacement power supply in the company’s memory testers. The heavy (and expensive) power supply would often get its contact fingers bent during the installation. The solution was to mount reinforcement between contact fingers. The new problem was that the reinforcement partially blocked airflow from the power supply. The solution was to analyze the system in Coolit. The simulation predicted that the redesign unexpectedly improved the thermal performance, apparently due to increased air turbulence. The validity of the simulation was reinforced by the fact that the downstream results matched the temperatures measured in the wind tunnel. The design change was quickly incorporated into production resulting in considerable savings to the company.

Over the past year, Coolit sales have grown exponentially and significantly exceeded projections for 1998. Who said that you have to be an Internet company to do that! Unlike in the first year and a half when most of our customers were new to the CFD area, this year a considerable portion of new Coolit customers switched from other CFD codes. As illustrated in the graph below, Coolit's growth rate significantly exceeds that of our main competitor and of the CFD cooling market itself, illustrating that Coolit is taking market share from other vendors. Flotherm’s growth rate dipped below the market rate since the introduction of Coolit in mid-1996 (Flotherm growth rate data are taken from their press releases and can be found on their web site). The CFD market is estimated to be growing by 25% annually.

This test case carried out at Nokia Research Center in Helsinki, was designed to provide a well-defined model for CFD analysis thereby eliminating potential uncertainties. The fin array was isothermally powered to within 1°C by electrical cartridge heaters. Temperature was monitored by a combination of platinum resistance sensors embedded in the cartridge heaters and thermocouples attached to the baseplate. Temperature and power dissipation were measured to within ± 0.2 °C and 1% respectively. To permit heat transfer rate calculations, a double-sided symmetry design was employed. The enclosure walls were water cooled to ensure isothermal surfaces and permit definition of fin array adiabatic wall temperature. Fluid velocity and temperature profiles were measured at the upper and lower opening of a central u-channel passage using hot wire anemometry, and salient features of enclosure fluid flow were observed using smoke flow visualization. Coolit simulation was run blind, i.e. without the knowledge of experimental data. As shown in the accompanying Applications Gallery article, Coolit's prediction was in excellent agreement with experimental data.